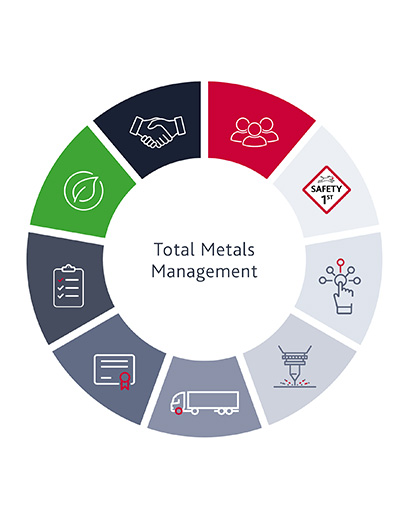

TOTAL METALS MANAGEMENT

Companies that operate in high-tech sectors demand a first-class service and quality standard as well as purchasing metals on a project-by-project basis.

TUBE LASER CUTTING

Provision of kit of parts ready for assembly

Capacity to process large volumes of project work with close tolerances and complex geometries

Ability to service contractual work and repetitive requirements

Flexible lead times

Processing Hollow Sections, Tubular Products, Beams, Columns, Split Tees, Angles and Channels

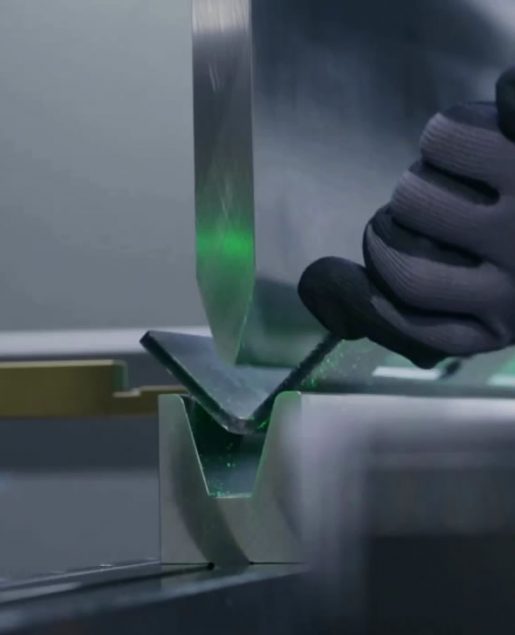

FLAT LASER CUTTING

Cutting Carbon, Stainless and Galvanised Steel, Aluminium and Weathering Steel

UKCA/CE marking to Execution Class 4

Cut quality (thermal best in class)

Cut tolerances (+/- 0.25mm)

Max cutting thickness 25mm on Stainless and 20mm on Mild Steel

PRECISION BENDING / FORMING

We offer precision bending and pressing of materials into bespoke three-dimensional shapes. The Bystronic Xpert press brake can deliver first-class bending results on parts up to 4100mm long, with a maximum of 320 tonnes of pressure. To prevent cross-contamination, we use dedicated tooling for Mild and Stainless Steel.

PROFILING

Ability to process large area plates up to 14m x 3.2m in a number of grades, ranging from structural steels through to pressure vessel, boiler and offshore grades

Volume and small batch profiling

All profiles fully fettled and shrink wrapped

Straight-line burning facility

Edge bevelling & weld preparation

WATER JET CUTTING

Cutting up to 200mm thick material

Cutting Stainless Steel, Duplex and Super Duplex materials

Max length 4010mm

Max width 2010mm

Cutting tolerance +/- 0.25mm

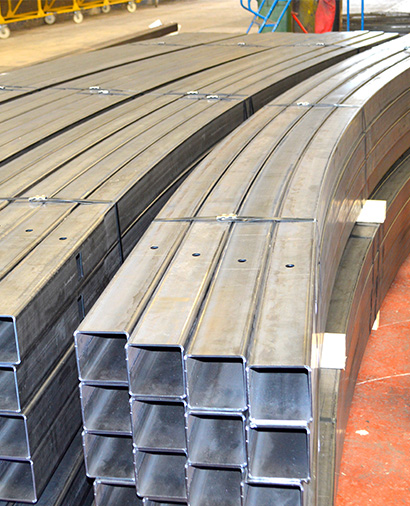

SECTION BENDING

From tubes, flats, rounds, solid rounds, solid squares, rolled steel angles, tee sections and channels, we offer section bending and can manipulate Mild Steel, Stainless Steel or Aluminium materials to your specific requirement.

FLOWDRILLING

The Flowdrill uses high rotational speed and high pressure to make holes in the desired material. The process is beneficial when there is a requirement for a thread in thin material without the use of thread inserts.

SHOT BLASTING & PAINTING

Our shot blasting & painting lines can handle plates and structural material up to 22m long, 1500mm wide and 500mm high. The maximum weight capacity is 10 tonnes. We offer a blast finish to SA2.5 in the paint colours of red and grey.

DE-COILING & SLITTING

We offer offers a comprehensive range of light gauge de-coiling, slitting and guillotining services.

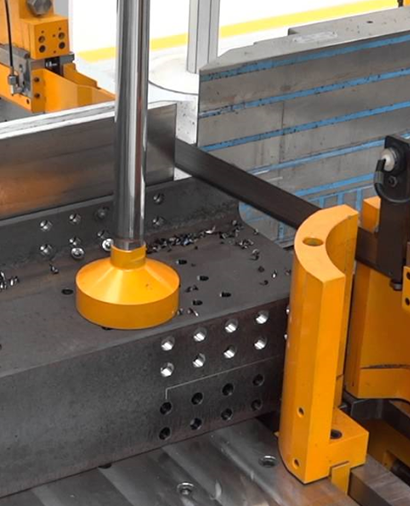

DRILLING

Our drilling lines are heavy duty, high speed, high performance, fully automated and accurate. Offering drilled and countersunk holes, adding value and reducing your first stage manufacturing costs.

SAWING

Sawing capabilities of sections up to 1300mm x 700mm

Handling lengths up to 22m with a mitre cutting of up to 60 degrees

The typical cutting tolerance that can be achieved is +/- 2mm on the length and +/- 0.5 degrees on the mitre cut – tighter cutting tolerances may be achieved by prior agreement

Ability to saw heavy-duty steel profiles, single beams, bundles or layers

PUNCH & SHEAR

Processing flat steel from 50 × 5 up to 500 × 25 and angle steel from 50 x 50 x 5 up to 160 x 160 x 12

Producing brackets, gussets, rectangles and squares

Ability to provide the de-burring of individual punched holes in plates

CNC ROUTING

Ability to precision cut, groove, chamfer, channel and engrave various materials, including Aluminium, Composites and plastics 5mm thick up to 100mm

Folding and bending Composite and Aluminium panels

Cutting bespoke shapes and sign panels in one-offs or in high volumes

2D flat-cut letters, logos and other shapes